Which shipbuilder "welder" technology is strong? The final of the province's shipbuilding industry welder skills competition was held in Nantong

Release time:

2019-11-21

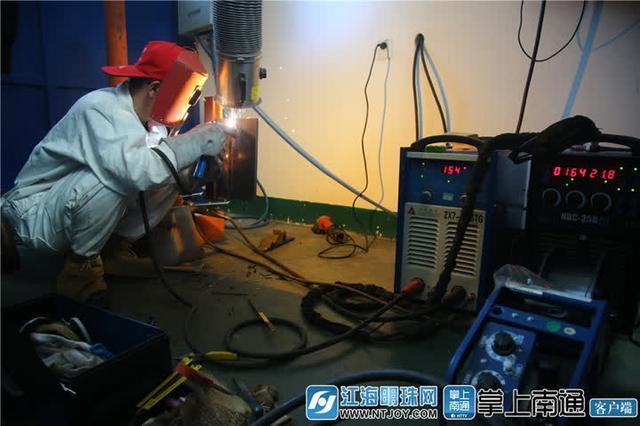

On November 20th, the final of the 7th “Nantong Aviation Academy Cup” shipbuilding industry welder skill competition in Jiangsu Province was held at Nantong Shipping Vocational and Technical College. There were 28 staff team representatives and 8 student senior group representatives from the shipbuilding industry in the province. Teams, 7 student intermediate teams represent teams. This competition starts on November 20 and ends on November 22. It is divided into theoretical examinations and operation skills competitions. The operation skills include grinding, spot welding test pieces, and RT flaw detection of test pieces. Participants will show their abilities. , Competing for "Jiangsu Provincial Technical Expert", "Jiangsu Provincial May 1 Innovative Expert", "Jiangsu Provincial May 1 Labor Medal" and other honors.

On November 20th, the final of the 7th “Nantong Aviation Academy Cup” shipbuilding industry welder skill competition in Jiangsu Province was held at Nantong Shipping Vocational and Technical College. There were 28 staff team representatives and 8 student senior group representatives from the shipbuilding industry in the province. Teams, 7 student intermediate teams represent teams. This competition starts on November 20 and ends on November 22. It is divided into theoretical examinations and operation skills competitions. The operation skills include grinding, spot welding test pieces, and RT flaw detection of test pieces. Participants will show their abilities. , Competing for "Jiangsu Provincial Technical Expert", "Jiangsu Provincial May 1 Innovative Expert", "Jiangsu Provincial May 1 Labor Medal" and other honors.

It is understood that Jiangsu Province has ranked No. 1 in the nation's largest shipbuilding province for 10 consecutive years, and the shipbuilding industry needs a large number of skilled personnel. Nantong, Taizhou, and Yangzhou are the three major shipbuilding bases in our province's shipbuilding industry. Among them, Nantong's share of shipbuilding completion accounts for 25.6% of the province's total, forming a group of Nantong COSCO Shipping, China Merchants Heavy Industry and other batches with strong international competitiveness. The professional general contractor, marine equipment delivery products basically cover all types from offshore to deep sea.

The Provincial Shipbuilding Industry Welders Skills Competition has been successfully held for six sessions. More than 1,200 employees in the shipbuilding industry have participated in the competition. The competition has awarded 6 contestants the "Jiangsu Province May Day Labor Medal" honorary title, and 72 contestants have won " "Jiangsu Technical Expert" and "Jiangsu Provincial May 1 Innovative Expert Honor", 108 players have obtained the qualification certificate of technician (senior technician), 36 players have obtained the senior professional certificate, and more than 100 players have obtained the qualification of ship welder. The certificate strongly supports the construction of a strong province in shipbuilding.

Nantong client reporter Pan Dongdong

Related News

Prospect of China's shipbuilding industry

2019-10-22